For printing and packaging industries, high-speed book shrink wrapping machine represents the pinnacle of ideal process equipment.

|

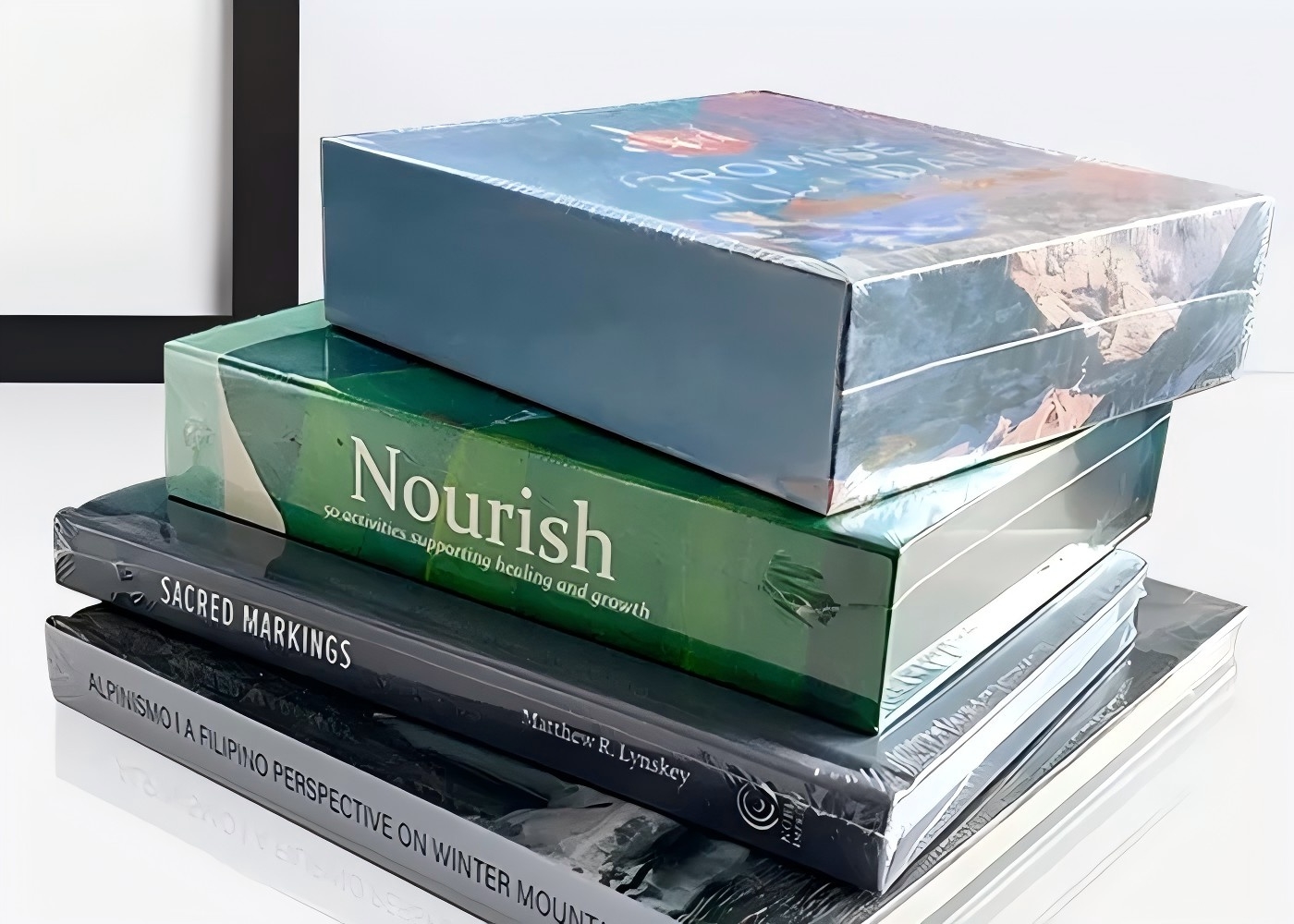

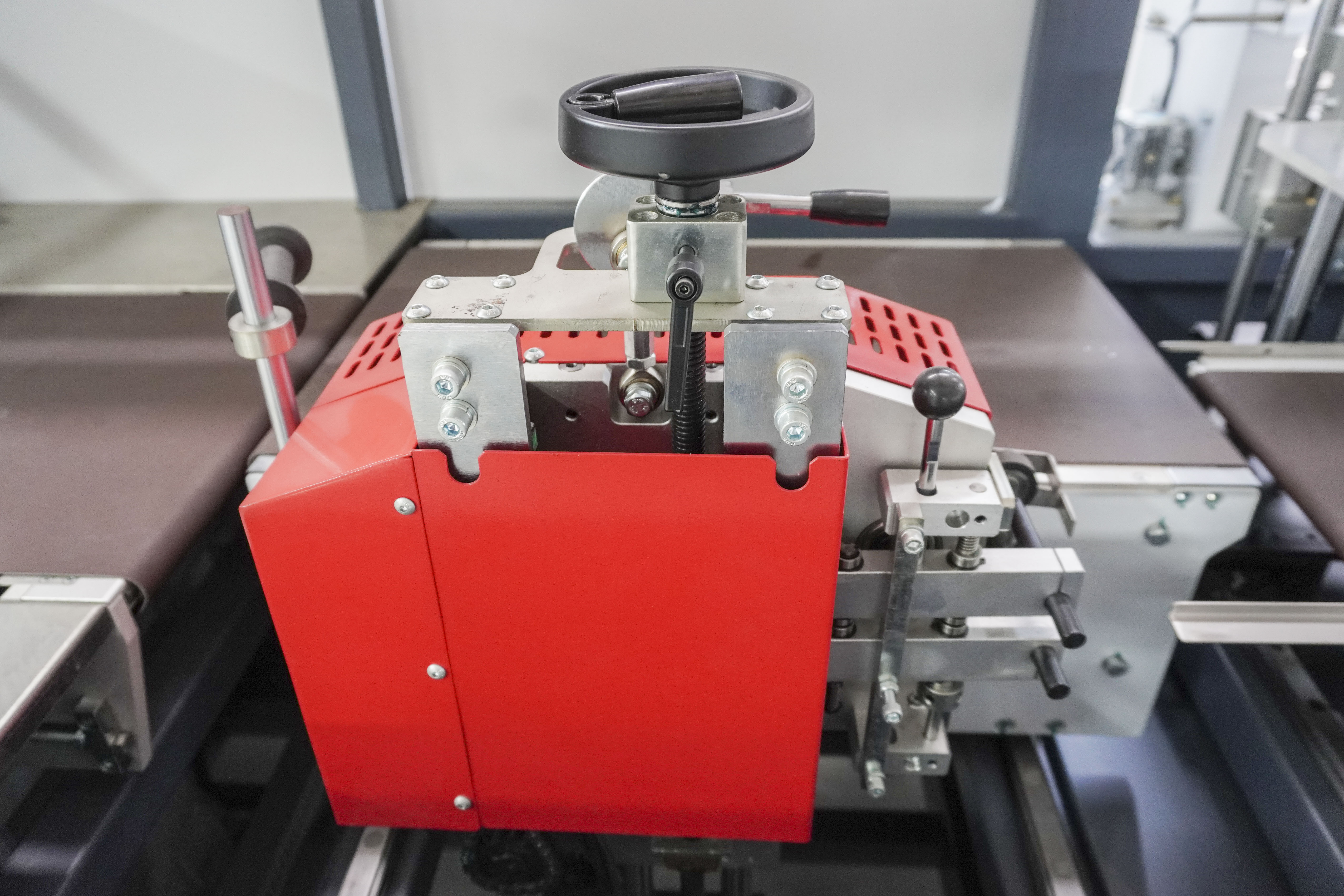

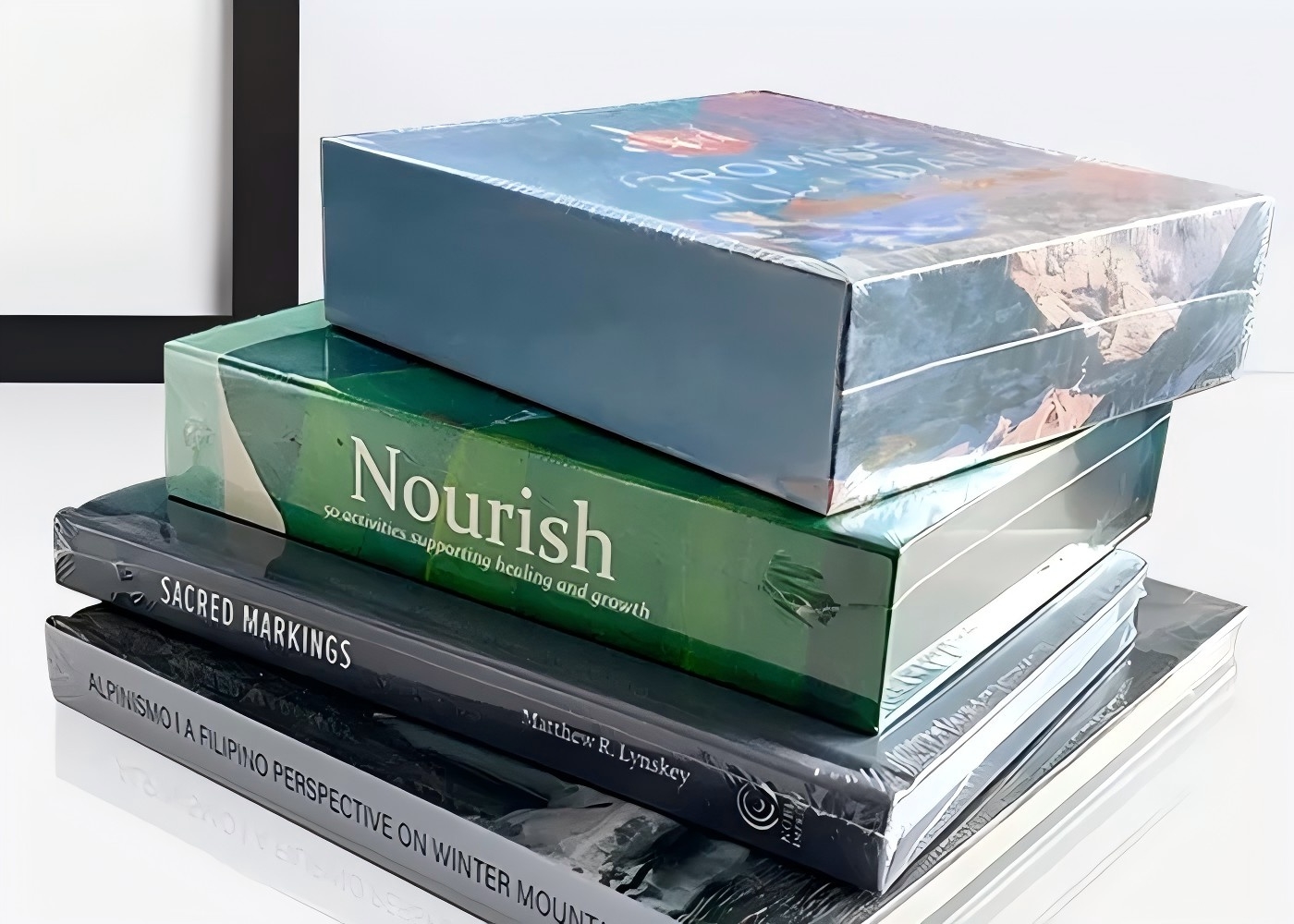

The journey from the bindery to the bookstore shelf is fraught with potential damage. Shrink wrapping provides a critical protective shield, and specialized automatic shrink wrap machines for books are the key to achieving flawless, retail-ready packaging efficiently. This essential book packaging equipment is meticulously designed to handle the diverse range of products emerging from book binding processes, including standard paperbacks, durable hardcover books, functional spiral bound notebooks, elegant journals, practical diaries, wire bound planners, and glued bound notepads. The clear film showcases the product while safeguarding it from dirt and debris, scuffs, and moisture, ensuring it arrives at its destination in pristine condition. What sets a dedicated book shrink wrapping machine apart is its tailored automation. The process begins at the automatic book feeding table, where products are conveyed steadily into the system, saving labor and minimizing handling. The core of the machine, the automatic sealing and cutting unit, utilizes advanced sensing technology. Equipped with two group electric eyes (horizontal and vertical), it can seamlessly switch between different product orientations and sizes, automatically adjusting the cutting size via electric sensors and timers. This intelligence ensures the shrink film bag is perfectly formed for each unique hardback type of book or notebook, eliminating waste and ensuring a tight fit.  The sealing itself is executed with finesse using a hot air knife featuring a Teflon coating and constant temperature heating. This specialized blade achieves continuous hot cutting at speeds up to 1 meter per second, resulting in good sealing and cutting effect. The Teflon surface is crucial for non-sticking, preventing any residue or film tearing (breakage) that could mar the product's appearance. This continuous thread sealing guarantees strength and zero pollution on the seal area, maintaining the aesthetic quality of the book cover – a vital aspect for retail-ready presentation.  Following sealing, the book enters the heat shrinking part, featuring a thermal cycle shrinker with integrated thermal control. Freely adjustable wind direction is paramount here. It allows operators to fine-tune airflow to ensure even and consistent shrinkage around complex shapes – think the protruding wire of a spiral bound book or the spine of a hardcover. Double layers of insulation within the tunnel enhance thermal efficiency (energy saving) and maintain a constant temperature, crucial for achieving a smooth, tight, and crystal-clear finish that professionally showcases products without distortion. This step transforms the sealed bag into a protective second skin.  For printing and packaging industries, this high-speed book shrink wrapping machine represents the pinnacle of ideal process equipment. Its high efficiency (reaching 80 pieces per minute) translates directly to faster time-to-market and lower per-unit costs. The automatic book unloading units complete the hands-off process. The machine's compatibility with various films, from low gauge polyolefin for retail clarity to thick polyethylene for heavy-duty shipping protection, makes it incredibly versatile. By reducing labor costs, eliminating bottlenecks, and ensuring consistent, high-quality, protective packaging, this system is indispensable for any binder or publisher aiming to deliver perfect, retail-ready books, notepads, and journals to the market. |

| Tag:book shrink wrapping machine,Shrink wrapping,shrink wrap machine |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!